Designing Risk Mitigation Workshops for Healthcare and Manufacturing Industries

Introduction to Professional Risk Mitigation Workshop Certification

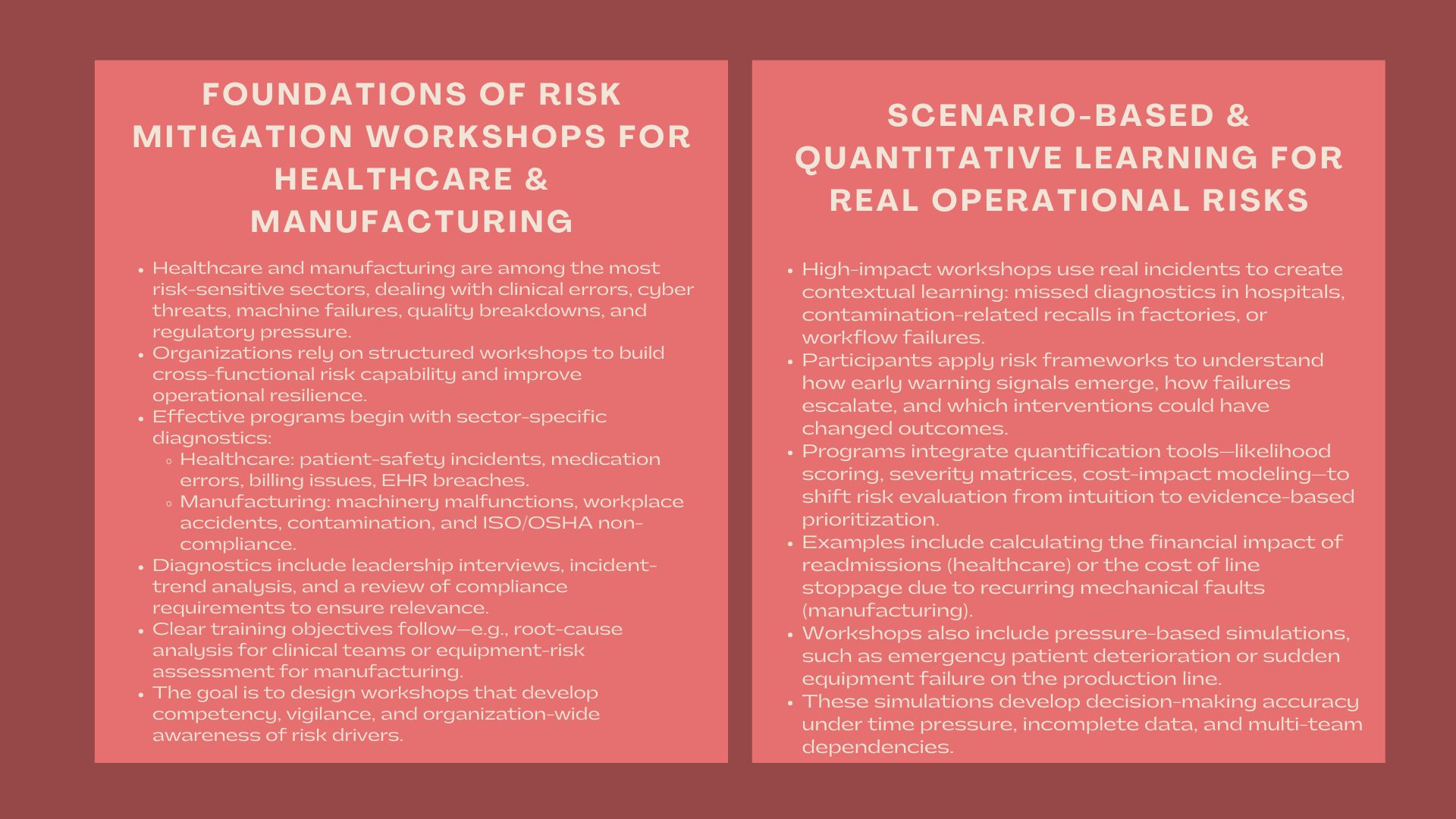

Such industries as healthcare and manufacturing rank among the most risk-sensitive sectors of the contemporary global economy. Medical facilities experience increasing regulatory burdens, clinical risk, and cyber risk and pressure. The manufacturing firms are battling with interruptions in their supply chains, machine risks, work stoppages, and failure of quality assurance. Since these risks both influence performance and resilience, organizations operating in these industries have been allocating more resources in special workshops that enhance cross-functional risk capabilities.

The development of the useful risk mitigation workshop involves the knowledge of the industry-specific problems and the capacity to address theory to the working practice. These programs do not only develop technical capabilities but also create the culture of vigilance that is required to safeguard assets, employees, patients, and production results.

1. Setting these Building Blocks of a Successful Risk Mitigation Program.

1.1 Sector-Specific Risk Diagnostics.

The first step to a successful workshop is a profound evaluation of the risk environment peculiar to the healthcare and manufacturing. Patient safety incidents, medication errors, billing errors, and electronic health record data breaches can be a risk in the healthcare sector. The threats in the manufacturing industry usually concern machinery malfunctions, accidents at the workplace, pollution, or non-adherence to international manufacturing practices. This can be achieved by performing early diagnostics and makes certain that the workshop is based on actual operational issues and not on their generalized frameworks.

Practically, this step of the diagnosis can involve interviews with the department leaders, research on the data about incidents in the past, and overview of the compliance requirements in the industry. The aim is to establish a training atmosphere in which the members will see their personal difficulties in the curriculum, which will make the workshop not only credible but very applicable. As the program progresses, the operational and financial risk mitigation training for healthcare organizations becomes a structured response to findings surfaced during the diagnostic stage.

1.2 Defining Training Objectives and Expected Competencies

After the identification of the key risks, the organizers define the competencies that participants should develop. In the health sector, they can be incident investigation, root-cause analysis, scoring of risks, and familiarity with the standards of clinical governance. Competencies in manufacturing may include equipment risk assessment, process failure investigation and safety practices that are OSHA compliant. Defined objectives would aid in determining the scope, content sequence and depth of the program.

These objectives are refined further using real-life examples. One of the goals that a hospital can establish is to minimize medication administration errors by providing risk-probing tools to nursing supervisors. A manufacturing facility can also strive to reduce the amount of time machines spend in the maintenance workshops by educating maintenance personnel about the presence of risk warning signs. Workshop design is more strategic and result-oriented when the objectives are measurable and apply to the needs of the organization.

2. Creating Hands on, Scenario-based Learning Modules.

2.1 Applying Real Incidents to Construct Contextual Understanding.

The most effective risk workshops are based on the case scenarios based on actual incidents. In the healthcare sector, one can consider a situation in which timely diagnostic outcomes were missed and caused clinical complications and explore the role of communication breakdown, workload stress, or technology limitations in the issue. In production, a situation may be a batch recall due to contamination, which causes a reversal of the sequence of how quality failures went unnoticed.

Through the implementation of risk framework onto real-world scenarios, the participants will understand how risks change with time and how timely intervention would have changed a situation. This contextual learning also enables the employees to get to know the weak signals in their respective operations and hence the training becomes immediately actionable.

2.2 Incorporating Practical Methods of Risk Quantification.

Risk mitigation is not something that can be discussed qualitatively; it is something that should be analyzed numerically. Successful workshops familiarize the participants with quantification instruments, namely, likelihood scoring, severity matrices and cost-impact modeling. These tools assist in the prioritization of risks avoided by both the healthcare and manufacturing teams in a more objective way rather than depending on intuition.

A hospital, to illustrate, can measure the financial effect of readmission that can be related to documentation mistakes, whereas a manufacturing plant can measure the price of the possible line stoppage because of a reoccurring mechanical defect. Such drills make the personnel understand the budgetary aspect of risk and substantiate the reason that proactive mitigation is an investment in safety and profit.

2.3 Decision-making Under Pressure Simulation.

Another characteristic of high level risk workshops is that real-time decision-making was simulated. Simulations can be used in healthcare and mimic an emergency situation when teams have to react to the sudden worsening of the patient. In production, it may be a simulation related to reacting to unexpected equipment failure or contamination during the shift business.

These simulations replicate the forces that employees are exposed to in the field, time, incomplete data, competing priorities, and cross-functional dependencies. Training on how to make proper decisions when under pressure will teach the participants good habits and get ready to face the actual operation issues.

3. Inculcating Compliance, Governance and Reporting Mechanisms.

3.1 Training in Regulatory and Accreditation Requirement.

One of the biggest motivators of risk management in the two industries is regulatory compliance. Joint Commission standards, HIPAA data protection regulation, and national patient safety guidelines are some of the frameworks that have to be incorporated into healthcare workshops. The quality standards of ISO, OSHA safety regulations of the workplace, and environmental protection requirements of the local area are usually included in the manufacturing workshops.

Incidentally, by implementing them within the curriculum, the participants do not only learn the existence of the rules but also the reasons why they are there and how the breaches of the rules lead to the operational and financial risks. This makes the training be on track with the governance expectations and best practices in the industry.

3.2 Teaching Documentation and Audit Ready Reporting Practices.

The process of risk mitigation cannot be complete without a regular documentation. Workshops educate the attendees how to document incidents and risk assessment, corrective actions and compliance evidence in standardised forms that can survive internal or regulatory audits.

Medical staff can exercise the generation of incident reports, indicating clinical situation, workflow failure, and corrective actions. Manufacturing teams can be taught to record the equipment risk checks, safety checks, and deviations found in the course of production. Such documentation exercises will assist the staff in comprehending how the flow of risk information within departments and the importance of the uniformity of reporting to support learning of the organization.

3.3 Continued Enhancement of Interdepartmental Cooperation.

The process of risk mitigation is cross-functional in nature. Hospitals need to have a combination of clinical, administrative, IT teams and manufacturing plants production, engineering, safety and quality teams aligned. Governance frameworks that are presented during workshops include risk committees, escalation schemes, and common dashboards.

Such examples may be the establishment of cross-functional huddles to look at the safety indicators or the introduction of dashboards to monitor the leading and lagging risk measures. Such collaboration mechanisms help in ensuring that the risks are not individually handled but handled throughout the organization. This is especially relevant for the risk assessment and management workshop for manufacturing professionals, where coordination between production and quality teams is essential for incident prevention.

4. Measuring the Impact of Training and Ensuring Long-Term Adoption

4.1 Tracking Behavioral and Process Improvements

An effective workshop has to deliver observable changes. Examples of the improvements that organizations follow include decreased incident rates, fewer production stoppages, better compliance scores, or better audit results. In healthcare, the measures can be reduced medication errors or the time spent on incidents. The indicators in manufacturing could be fewer downtimes or better yield rates.

4.2 Integrating Ongoing Learning in the form of Refresher Programs.

Due to risk environment changes, constant updating of teams through refresher programs is applicable to ensure that teams meet the new standards, technologies, and industry practices. The leanings are reinforced with short quarterly sessions or re-certifications which ensure that the teams remain risk aware in the long run.

4.3 Strengthening the Follow-Through with Digital Tools.

Online tools like risk dashboards, audit-management tools, and mobile reporting applications can be used to make operational workshop learning. The tools make the risks visible and provide supervisors with a chance to monitor the progress of each unit in real time.

Conclusion

The development of effective risk mitigation training in healthcare and manufacturing organizations will have to be based on the alignment of training with actual operational issues, the use of simulation-based learning, and the inclusion of regulatory expectations in the program outlay design. These workshops enhance the level of organizational resilience and safety by integrating diagnostics, practical modeling, and cross-functioning. Since risks in both industries are becoming more complex due to medical technology malfunctions or global supply chain setbacks, a formal training program will continue to be a critical investment in long-term stability, performance, and compliance.