Case Study: Manufacturing E-Learning Services Strengthening Operational Excellence and Workforce Capability Through Digital Learning

Background on Case Study Manufacturing E-Learning Services

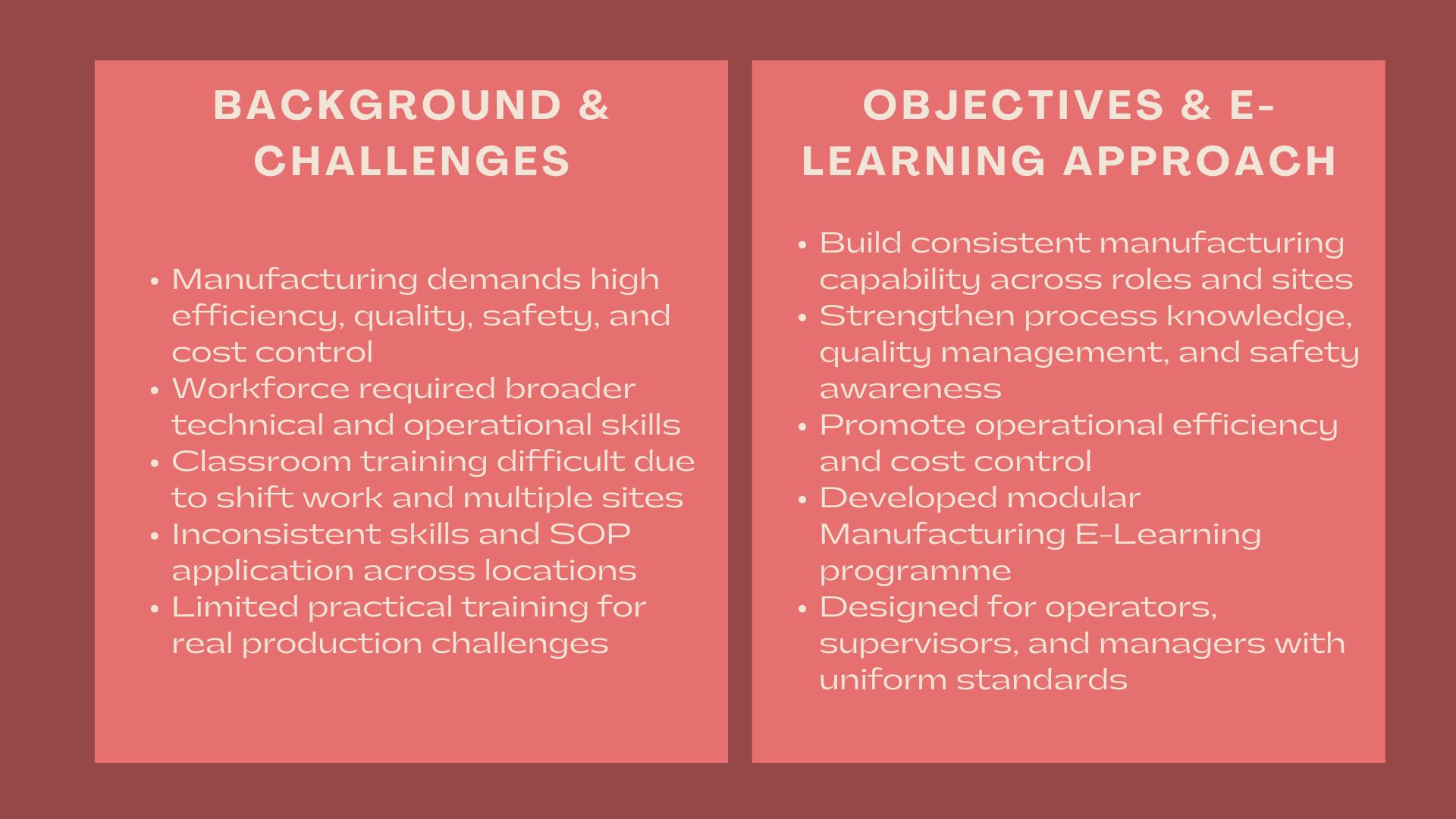

The manufacturing organisations work in an environment where efficiency of operations, quality control, safety and cost management play a vital role in the long term competitiveness of an organisation. With manufacturing being increasingly sophisticated, technology-intensive, employees in production, engineering, quality, supply chain and management functions are being demanded to acquire a wider and deeper range of technical and operating skills.

The classical classroom-based training models are often unable to address the demands of the contemporary manufacturing organisations. The working schedules (shift work), locations of the facilities that are geographically spaced and minimisation of production downtime make it hard to provide regular and prompt training. Moreover, there are faster changes in technology of manufacturing and the regulatory and safety standards that necessitate constant upskilling of the labor force.

In order to overcome these dilemmas, a manufacturing based organisation hired our company to develop and present an overall manufacturing E-Learning course. It was aimed at developing a scalable, practical and flexible digital learning platform that would improve the workforce capability and assist operational excellence.

Issues and Challenges

The organisation had a number of training issues in the manufacturing industry that were encountered before the engagement.

The lack of uniform knowledge and skill levels at production locations and groups was one of the major challenges. The employees were of different experiences and exposures to manufacturing best practices whereby there was inconsistent application of standard operating procedures and quality controls.

The other problem was a lack of access to training. Training in the classroom could necessitate the stopping of production or the absence of some of the key players in production, and it was hard to guarantee the wholesome involvement without even affecting production.

There was also additional complexity of the health, safety and compliance requirements. The manufacturing settings are highly regulated and governed by safety regulations that demand regular and frequent training in order to make sure that the operational requirements are addressed and pose less risk to the operations.

More job relevant and practical learning was also required. The available training programmes were mostly theoretical and failed to capture practical challenges observed in the manufacturing process like process optimisation, equipment downtime or quality variation.

Objectives

The interaction sought to create an E-Learning solution of manufacture, which would enhance the capability of operations and help sustainability of the business.

Key objectives included:

- Establishing a firm base in the manufacturing processes and operations.

- Enhancing the knowledge of quality management and constant improvement.

- Improving the safety and compliance consciousness.

- Promoting cost control and operation effectiveness.

- Providing self flexible learning in multiple locations.

The programme had to be applicable to both the employees at various levels, both the shop-floor operator, and the supervisors and managers and have a consistent standard of learning throughout the organisation.

How We Helped

Our Manufacturing E-Learning programme was designed in a modular way to include the main concepts of manufacturing, best practices in operations, and applied learning.

The programme started with the basics of manufacturing that exposed the learner to the processes of production, the design of work flow and the importance of manufacturing to the overall value chain. This helped give an understanding base that was used by all participants.

The later modules were concerned with the efficiency of operations and process improvement. Things were such as lean manufacturing concepts, waste minimization, productivity, and simple concepts of performance measurement.

The programme centered on quality management. The students were familiarized with the quality control techniques, root cause analysis and constant improvement strategies, and it was backed by real life examples that are applicable in the manufacturing setting.

During the learning process, health and safety training was incorporated in the process. Safety awareness, identifying the hazards, and adherence to safety standards in the workplace were dealt with via modules to support the necessity of safe and responsible practice.

In order to make it more practical, the programme included real-life manufacturing situations and case-study learning. Students demonstrated the concepts to scenarios like bottlenecks of processes, defects in quality, and challenges in the utilisation of equipment.

Learning Design and Delivery

The Manufacturing E-Learning programme was modeled in such a way that it was not only interesting and practical but also affordable enough to be used by a variety of people in the workplace.

The materials were presented in short and narrow modules consisting of instructional videos, explanations of the visual processes, and practical examples. Complicated operation principles were broken down into well-organized structures and well defined step-by-step instructions.

The interactive aspects of learning (quizzes, scenario-based questions, practical exercises, etc.) facilitated learning and active engagement.

The online platform where the training was conducted at the speed of the employee enabled them to work through training and production shifts without disrupting the production process as the learning results remained consistent.

The modular structure was also easily updated to ensure that the organisation could update content as new processes, technologies or regulatory requirements forced them.

Outcomes and Value Delivered

As demonstrated in this case study, the Manufacturing E-Learning Services is useful in creating scalable, consistent, and practical workforce capacity.

Workers gained better knowledge of the production process, quality control and safety, facilitating more efficient and effective operations. Reduced ignorance in terms of the principles of continuous improvement helped to enhance a culture of operational excellence.

On the organisational side, the e-learning solution was a reasonable and scalable method of training, which could be implemented in more than one location without disrupting the production. The uniformity of standards of learning was a measure that facilitated minimization of variation in practices and enhanced operational performance.

The programme also created a system of learning that could be built upon in the long-run, both to contribute to the development of workforce and resilience of organisations.